GAS TURBINE INLET AIR FILTERS

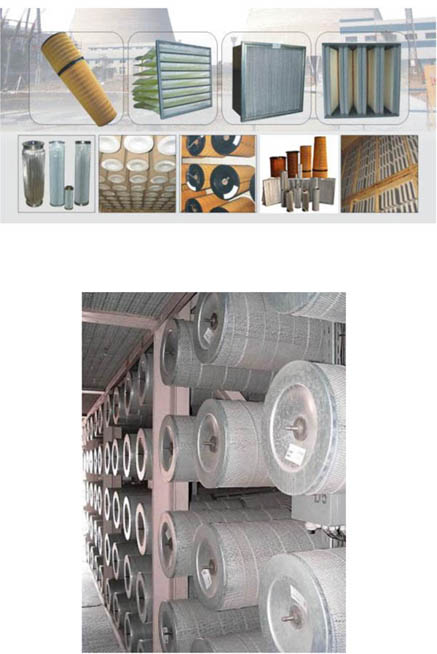

EnviTec manufactures a complete line of replacement gas turbine inlet air filters, including static pre-filters, static final filters and pulse jet cartridge and conical filters. Our filters are suitable for all environments, including off-shore and marine, and are compatible with all gas turbine brands and models.

The purpose of the inlet filter system is to protect the gas turbine from contaminants in the inlet air. Particles entering the gas turbine can cause erosion or fouling of the turbine internals. Erosion is mainly caused by coarse particles above 5 microns in size while smaller particles in the sub-micron size cause fouling of turbine blades and cooling coils resulting in reduced performance. Therefore, effective filtration of small particles and airborne salt is critical to the long term efficient operation of the gas turbine.

EnviTec’s gas turbine filters offer inlet air filtration protection at a very economical cost. Our filters can replace any filter brand and model and are compatible with all gas turbine makes and models. In addition, we offer pre-filters than can be applied to existing air inlet systems where pre-filters are not present, resulting in longer cartridge and conical filter life.

EnviTec EVTF Gas Turbine Filters

Static Pre-Filters

- Extended Surface Filters

- Bag Filters

- Cartridge and Conical Filter Sleeves

Static Final Filters

- Bag Filters

- Medium Filters

- High Efficiency Filters

- V-Bank Filters

Pulse Jet Filters

- Cylindrical Cartridge Filters

- Conical Cartridge Filters

FEATURES

GENERAL

BAG FILTERS

V-BANK FILTERS

PULSE JET CARTRIDGE and CONICAL FILTERS

|