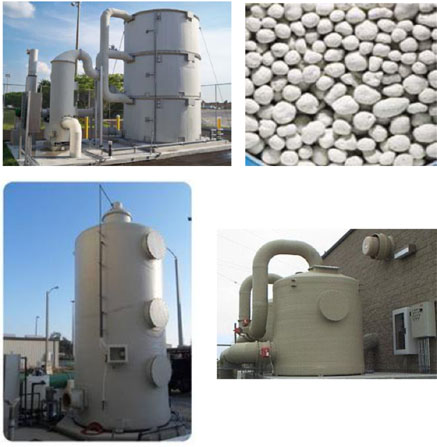

ODOR REMOVAL SYSTEMS - WASTEWATER

EnviTec’s odor control systems are used extensively in waste water treatment plant and pump lift station applications where odor removal is required. These systems can be single or multiple stage units utilizing biological, wet scrubber and/or carbon media technologies. EnviTec’s odor control systems effectively eliminate up to 99.9% + of H2S, ammonia, mercaptan, as well as many other odors.

EnviTec’s EVT BTR Biotrickling filters are biofilters, where an aqueous phase is trickled over the packed bed, and the packing is made of synthetic material. The trickling solution contains essential inorganic nutrients such as nitrogen, phosphorous, potassium, etc. and is recycled. Biotrickling filters are the most effective type of biofilters for the treatment of compounds that generate acidic by-products, such as H2S. They can be built taller as compared to other types of biofilters.

EnviTec Carbon Absorbers are designed to remove odor-causing components such as hydrogen sulfide, mercaptans, organic acids, aldeheydes, and ketones as well as a variety of organic solvent vapors in various industrial and municipal applications. Single bed units are available for capacities up to 15,000 CFM. Dual bed units are utilized for higher capacities.

To see EnviTec’s wet scrubber systems please click here.

ODOR PROBLEMS SOLVED!

EnviTec can provide effective solutions to treat air streams from 50 cfm to over 500,000 cfm, and to meet the needs of facilities ranging from lift/pump stations to dewatering/sludge-drying operations, and everything in between. All EnviTec units are compact state-of-the-art providing proven, exceptional performance, featuring our proprietary synthetic media in our biofilters that delivers uniform performance, across the media bed and across time.We also manufacture two-stage odor control systems for lowest possible emissions. These systems combine either our BTR biotrickling biofilter technology or our wet scrubbers with an Envitec carbon polishing stage.

APPLICATIONS

- High H2S

- Wastewater treatment plants

- Head works

- Grit removal, bar screens

- Pumping lift stations

- Pulp & paper, biogas generation and landfill applications

- Roughing filter

- Ammonia (NH3) removal

- Methanol, MEK, Acetates, Formaldehyde

- Industrial Applications for VOC removal.

FEATURES

BIOFILTERS

CARBON SYSTEMS

|